- Home

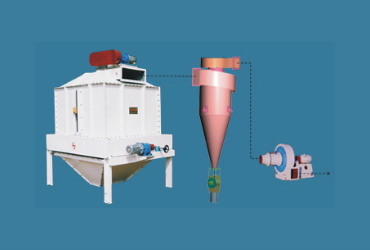

- COUNTER FLOW COLLER

Hot pellets coming out from Pellet Mill are required to be cooled near ambient temperature to remove excess moisture and heat to improve the shelf life. Counter flow Coolers are fast replacing the old cross-flow or horizontal coolers as these are compact, maintenance free & highly efficient.

PRINCIPLE

In Counter flow coolers product continuously moves downward direction in a bed of product in "first in first out manner" while cool air passes through product in upward direction. By the time product and air pass each other, they exchange heat & moisture.

CONSTRUCTION

It is a rectangular chamber made of SS-304 construction having an Air- Lock on top for entrance of material without air escape and a triple-grid-gate for discharge of material.

A stationary or rotating product distributor is installed to evenly distribute the entering product over product bed. A uniform bed height is maintained inside the chamber which can be increased or decreased to control the retention time by altering the position of level sensor which also initiates discharging mechanism.

Atmospheric air is sucked through the product layer by I. D. Fan which has butterfly valve to control the optimum volume of air required for cooling. Air can also be controlled by using a variable frequency A.C. Drive by altering the RPM of Blower.

The exhaust air is hot & moist and carries the dust particles with it. Dust is removed from exhaust air by installation of a Cyclone. It works on the principle of centrifugal forces.This has an Air Lock below it.

It is very essential to separate dust (fine feed) from exhaust air to avoid shrinkage and air pollution. Properly designed Cyclone with Air Lock at bottom deliver clean air to atmosphere.